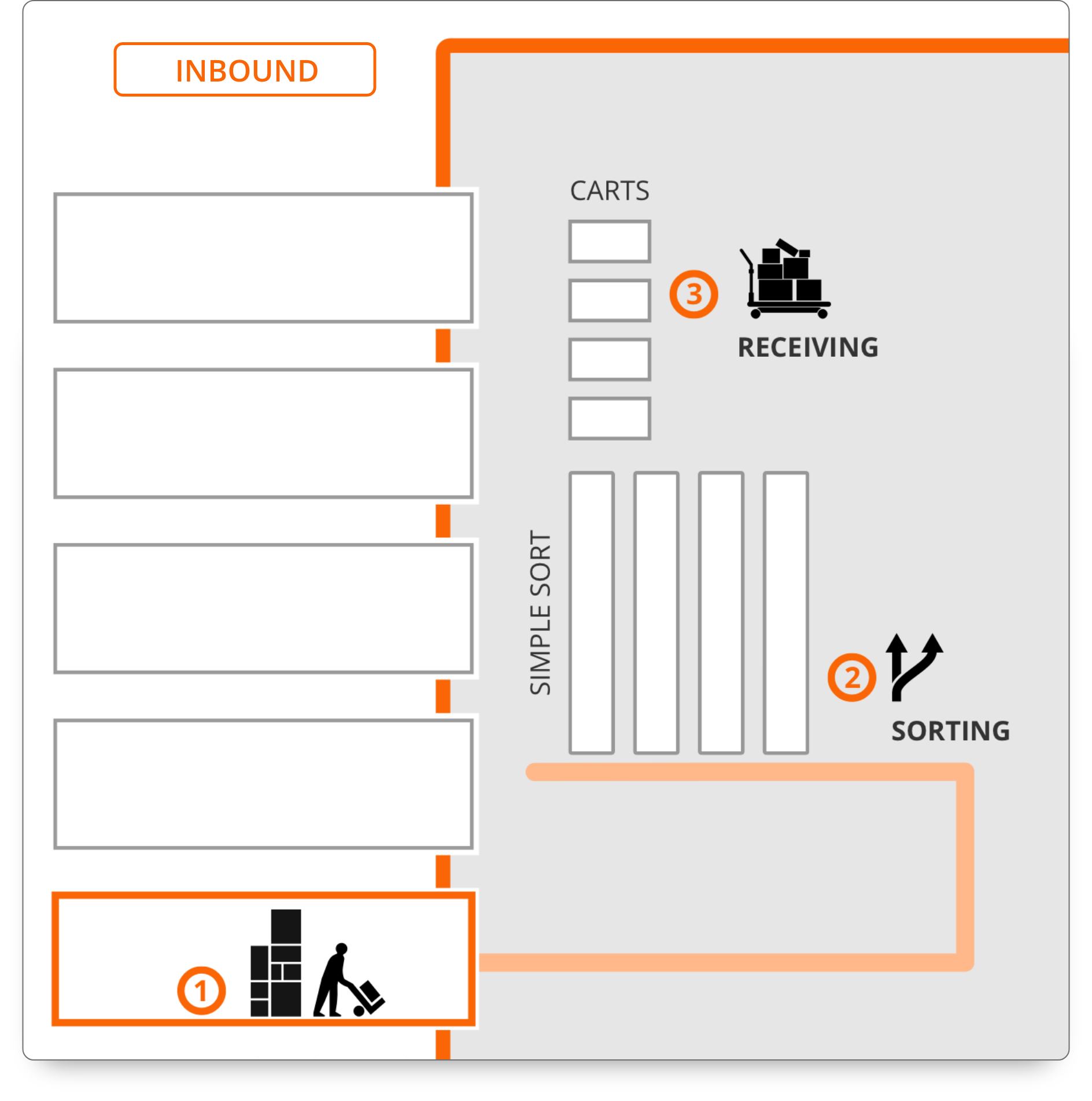

Inbound Simple Sort

A new process of unloading trailers at The Home Depot's Fulfillment Centers.

ROLE

Product Designer

RESPONSIBILITIES

User Research, Usability Studies, Interaction & Product Design

TIMELINE

Jan - Feb 2019

The Problem

Trailers were being unloaded manually by the inbound associates. On an average it took 2-3 days to unload an 18,000 item trailer. This caused delays in inventory replenishment within the fulfillment center and as a result, items were

not quickly available for customers to shop.

Due to manual unloading, the associates were getting tired quickly which also resulted in further increase in trailer unloading time and impacted their productivity.

How might we enable the Inbound Receiving Associates to efficiently sort the items being unloaded from a trailer and the Inbound Leaders to configure and manage the Simple Sort system?

Defining Success

The goal of the new trailer unloading process was:

⇨ Sort an item in less than 10 seconds.

⇨ Unload trailers within the same day.

⇨ Eliminate sorting bottlenecks.

Hypothesis

Physical System

To overcome the issue, the Operations Engineering team decided to implement a mechanized unloading process called Simple Sort. My team was tasked with designing and building

software that would assist the floor associates while they worked on the Simple Sort system.

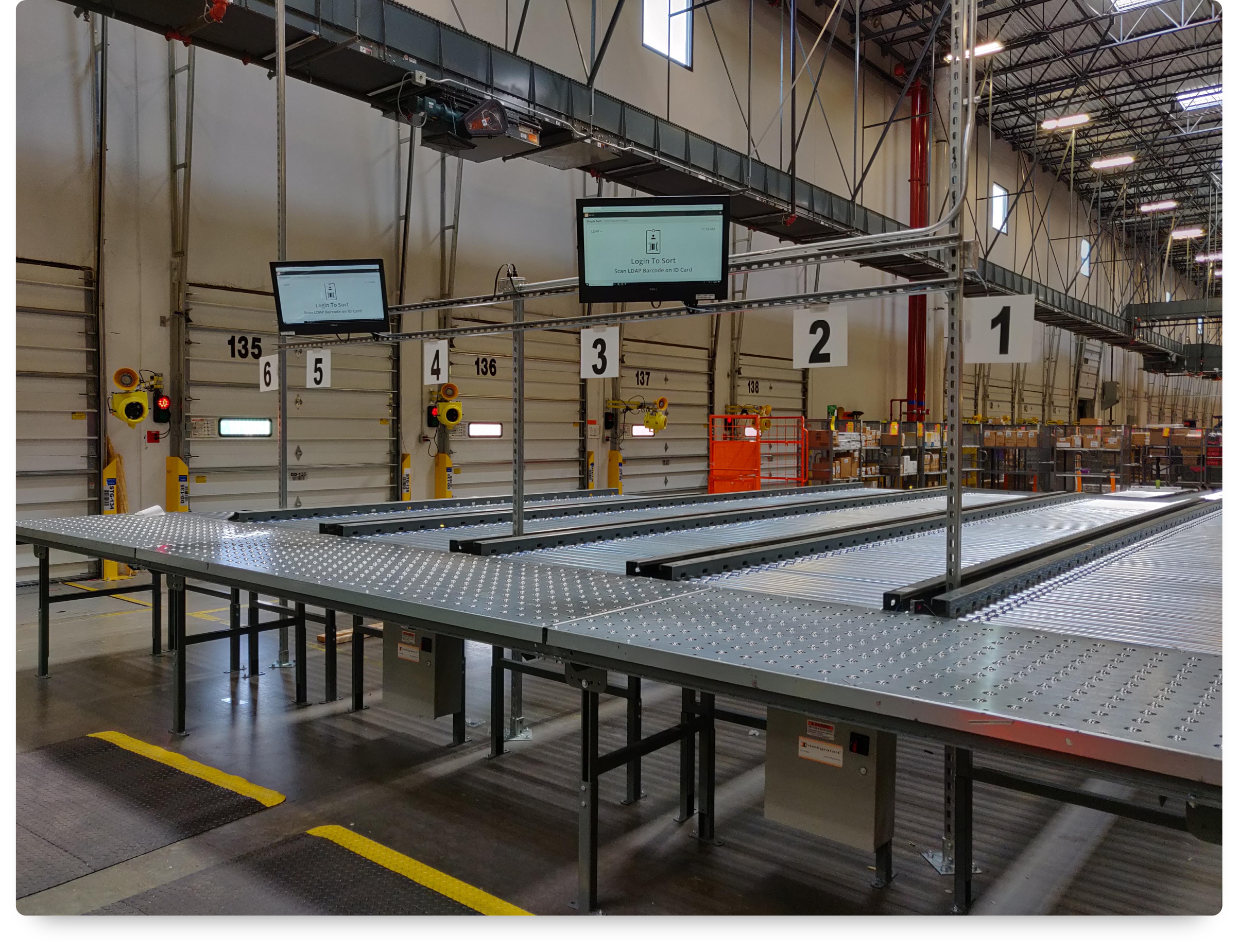

The new Simple Sort system involves a mechanized conveyor system to quickly unload and sort the items coming out of a trailer.

We believe, by implementing a mechanized sorting system to unload and sort items, the associates will be able to unload the trailers faster. We will know this to be true when we see trailers being unloaded in under a day and a reduction in sorting bottlenecks.

Research

To understand what was causing the delays and the impact of the problem, we visited a fulfillment center to learn more about the process.

Methods Used

Contextual Inquiry

User Interviews

Research Insights

Some of the key findings from our research were:

Manual Process

Unloading the trailers was a time-consuming manual process. On an average, it was taking around 2-3 days for a fully-loaded trailer to be unloaded.

Sorting was time-consuming

Sorting was a time-consuming effort since the receivers had to manually check every item/pallet causing sorting bottlenecks.

Sorting Bottlenecks

As a result of sorting bottlenecks, the items were not available for the picking associates to pick despite being available within the building for customers to shop.

Troubleshooting slows unloading

When items coming out of the trailers had issues, it would slow down the unloading process causing further delays.

Icon Credits: Luis Prado, Edwin PM, Thomas Deckert from the Noun Project

Ideation

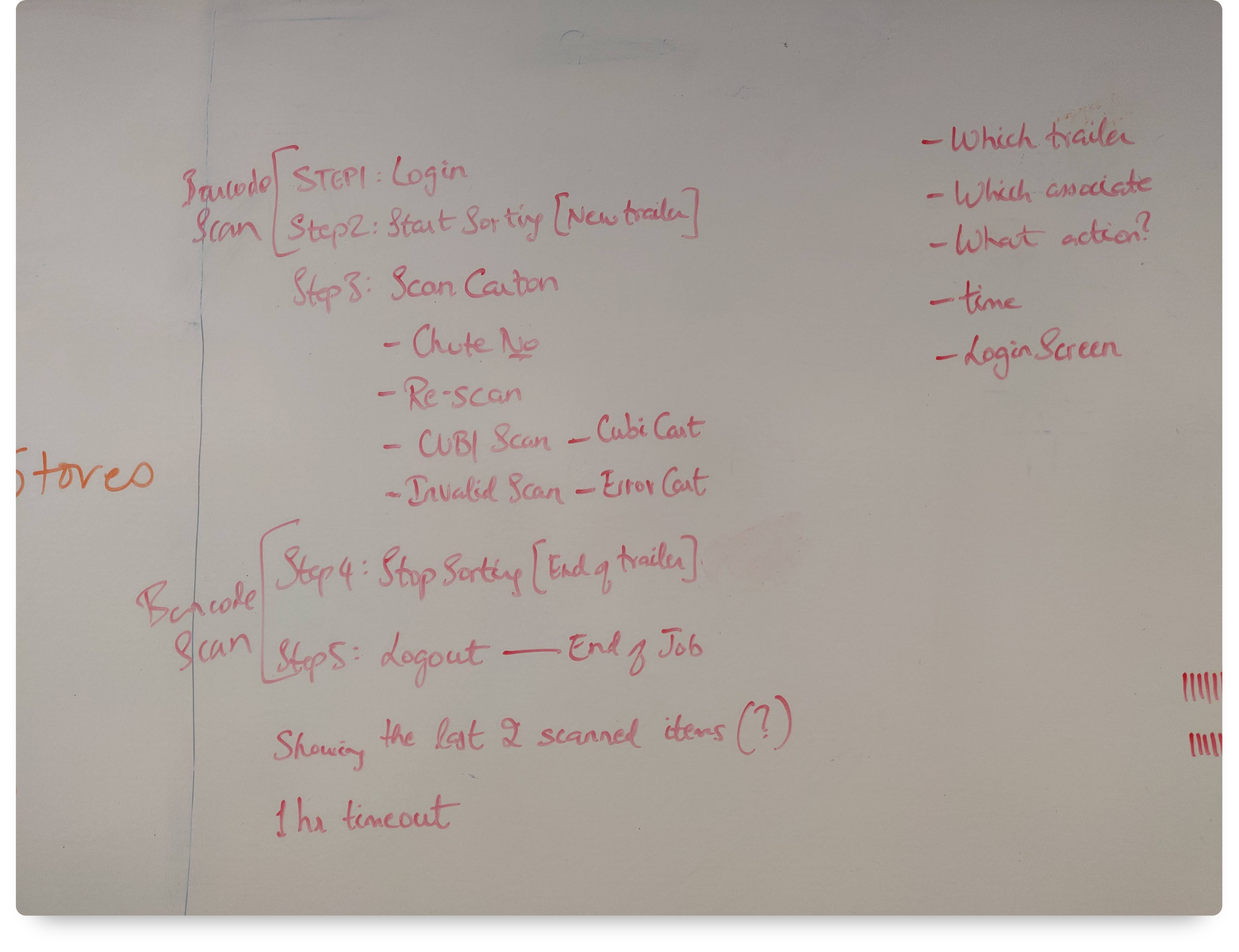

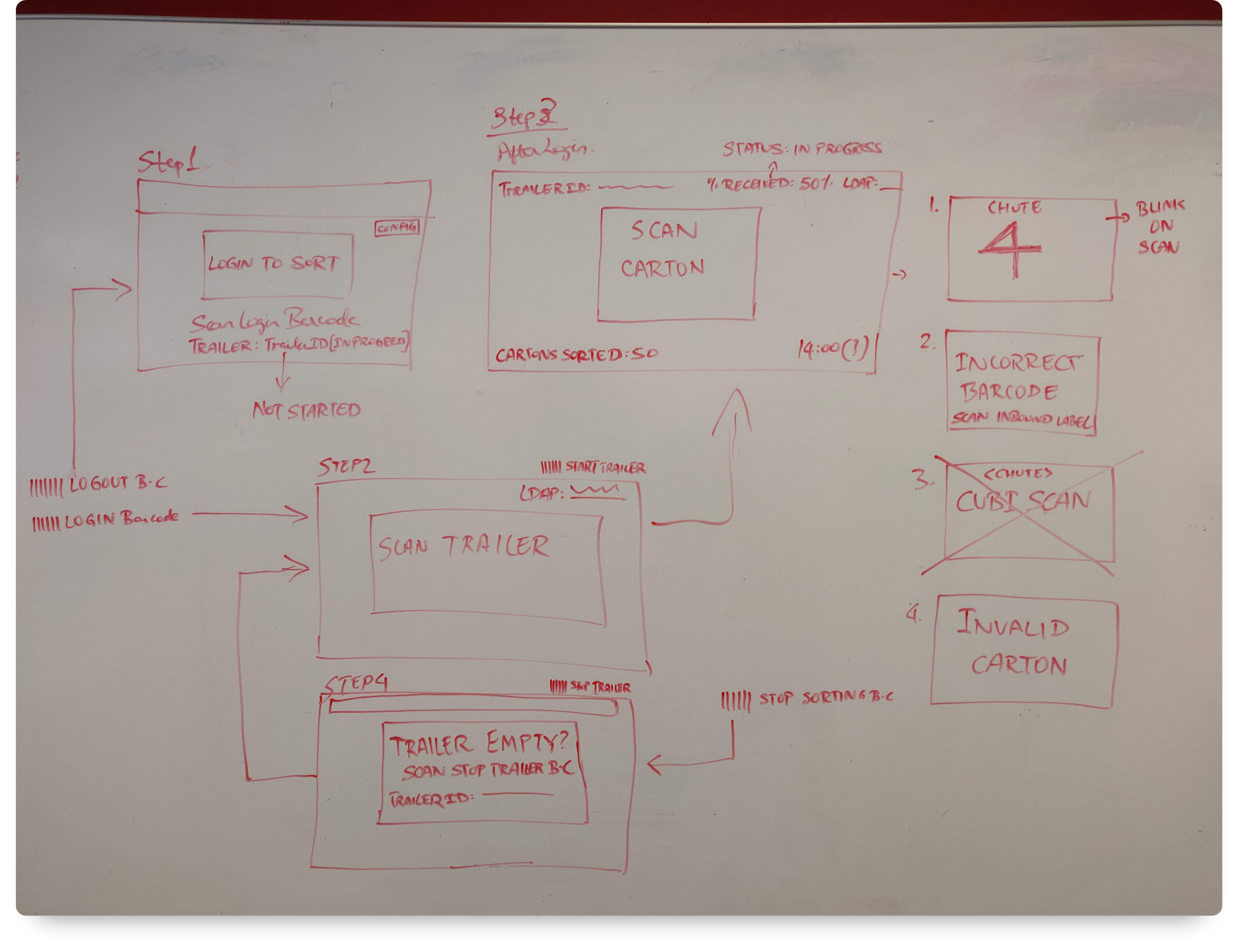

Whiteboarding

With a good understanding of the problem and the users' needs, we started thinking about ways to address those needs by whiteboarding the user-journey and flow within the app. The session involved the developers, PM, business owner while I was the facilitator.

How might we help the associates sort the items as they're being unloaded from the trailers?

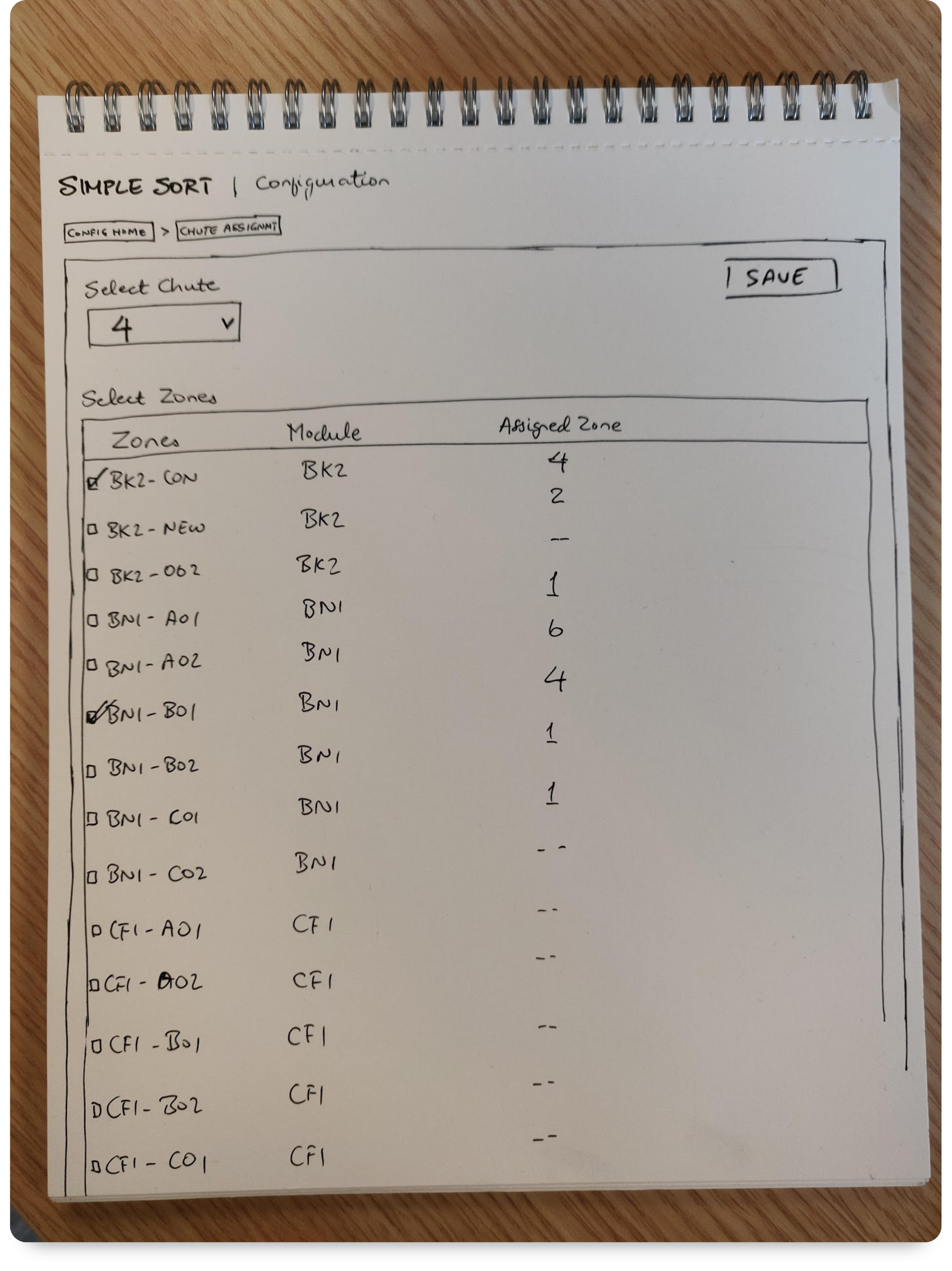

How might we allow the Inbound Leaders to configure and manage the Simple Sort system?

Defining the user flow for the new unloading process.

Brainstorming the user journey through the app.

Sketching the Config app.

Initial Designs

From the brainstorming, we hypothesized that the Receiving associates would need a wall-mounted display that tells them how to sort the items as their get unloaded and a desktop dashboard for the Inbound Leaders to configure and manage the Simple Sort system.

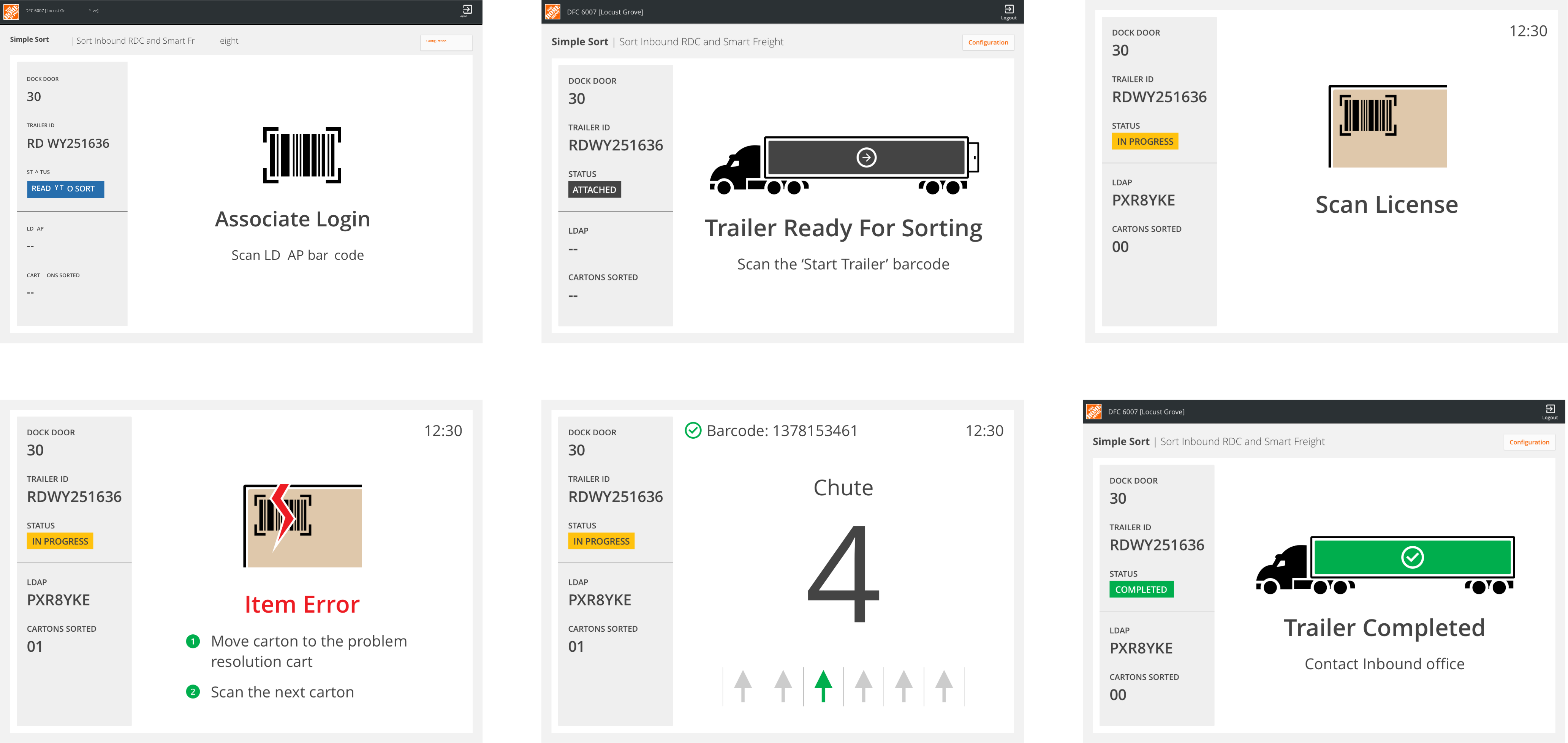

The screen of the first version of the prototype that was used for the usability studies.

Usability & Iterations

Once we had our solution hypothesis, we put the prototypes in front of the users to validate our assumptions and hypothesis.

Since the mechanized portion of the Simple Sort was not live, we had to do a wizard-of-oz usability testing. My team and I pretended to be the simple sort system and as the associates scanned the dummy boxes, we were moving the boxes

and changing information on the screen. It was challenging to keep the biases to a minimum and get the most accurate feedback from the associates, but also fun.

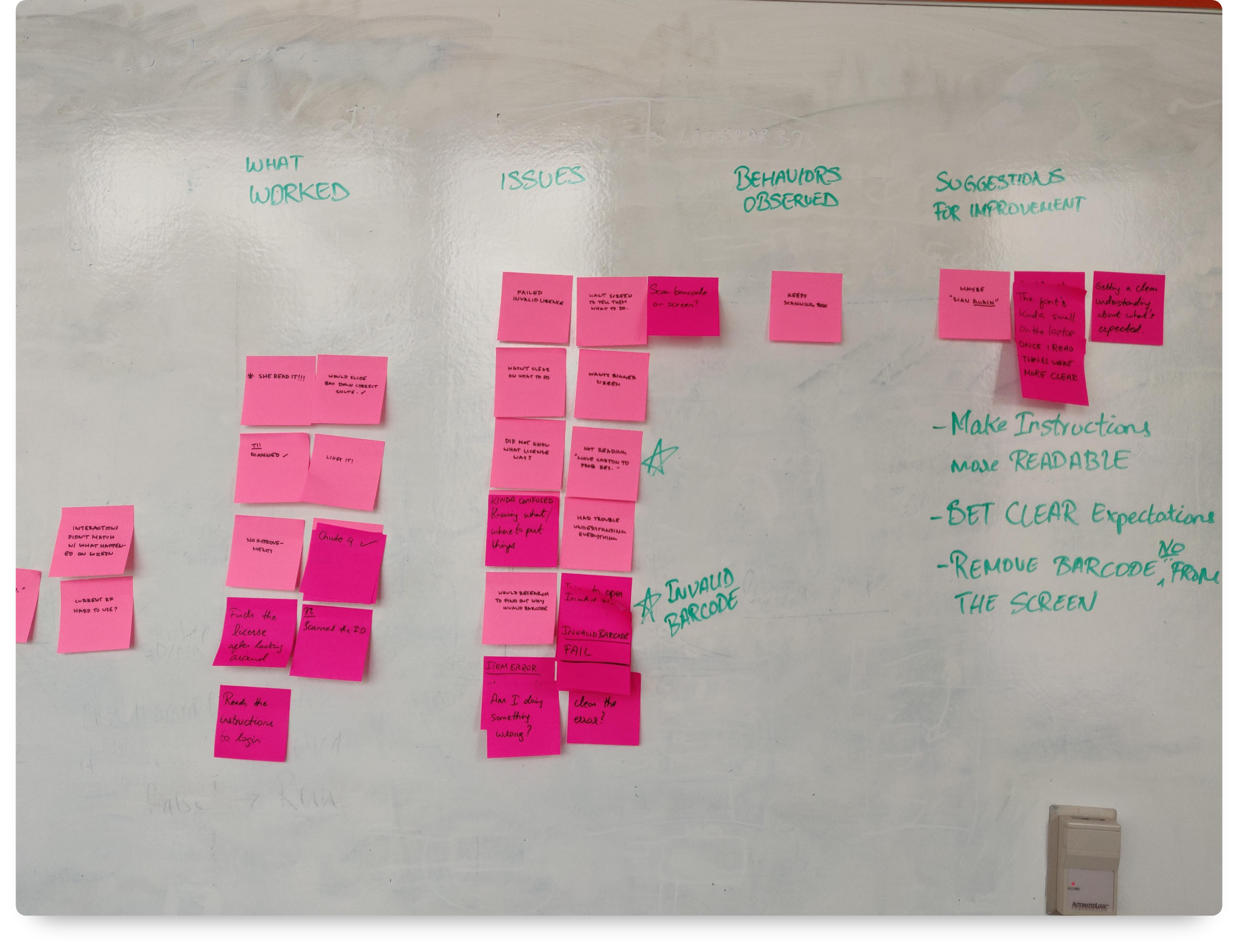

Synthesizing the usability data.

Findings from the usability study.

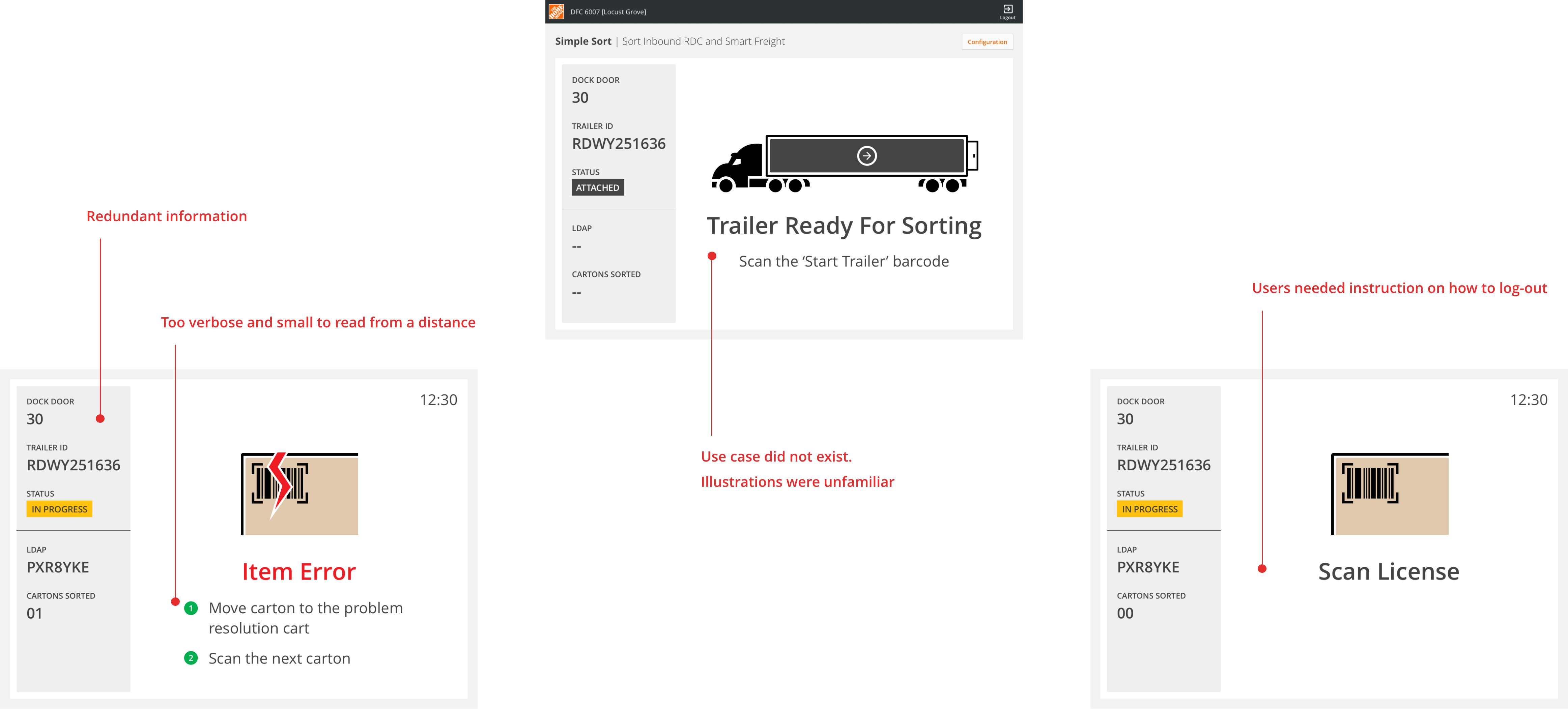

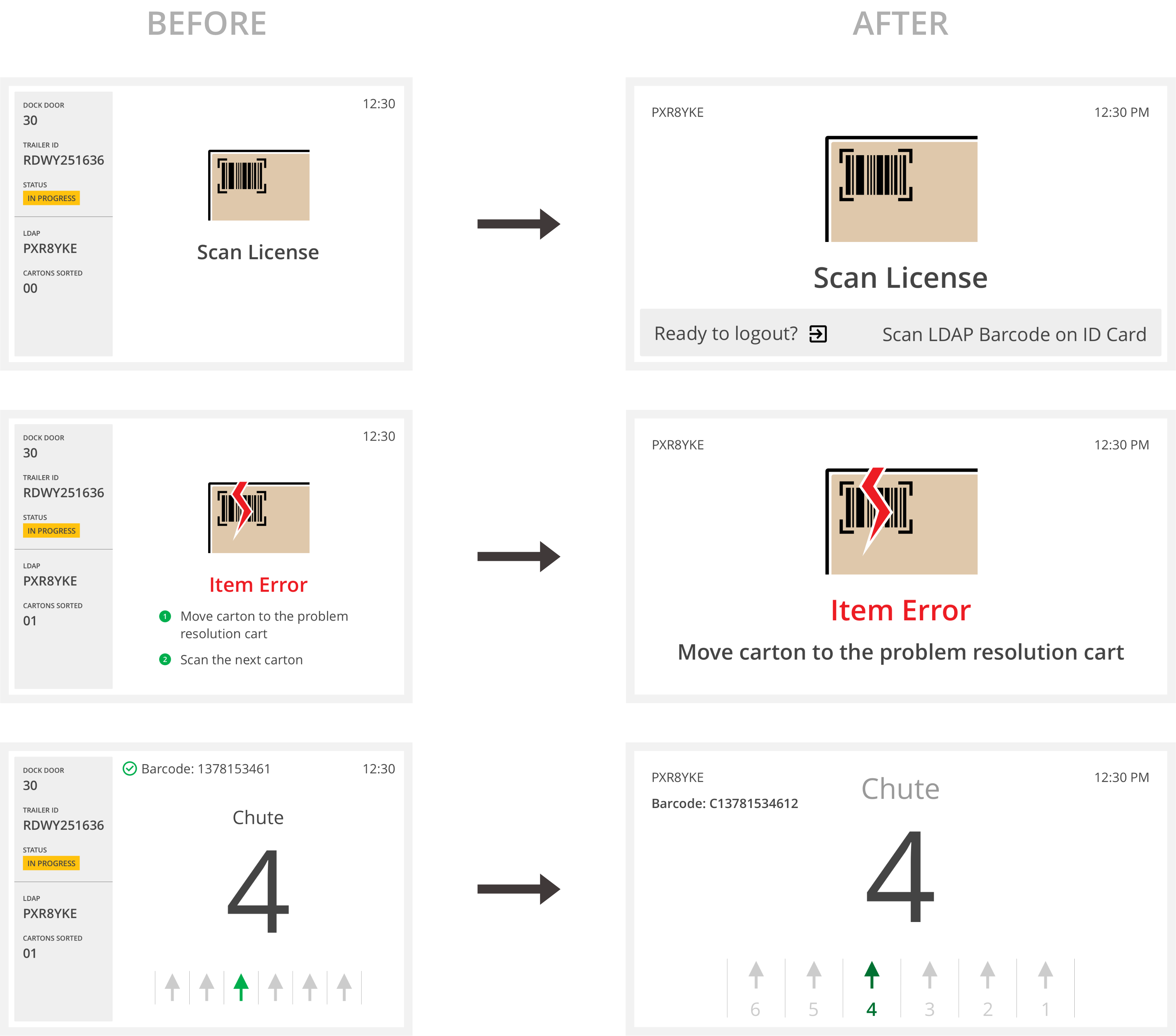

Iterations made based on the usability learnings

Final Design

The learnings from the usability studies helped inform the final version of the apps. This was also the first time an app of this scale was designed for large screens in the Fulfillment Centers.

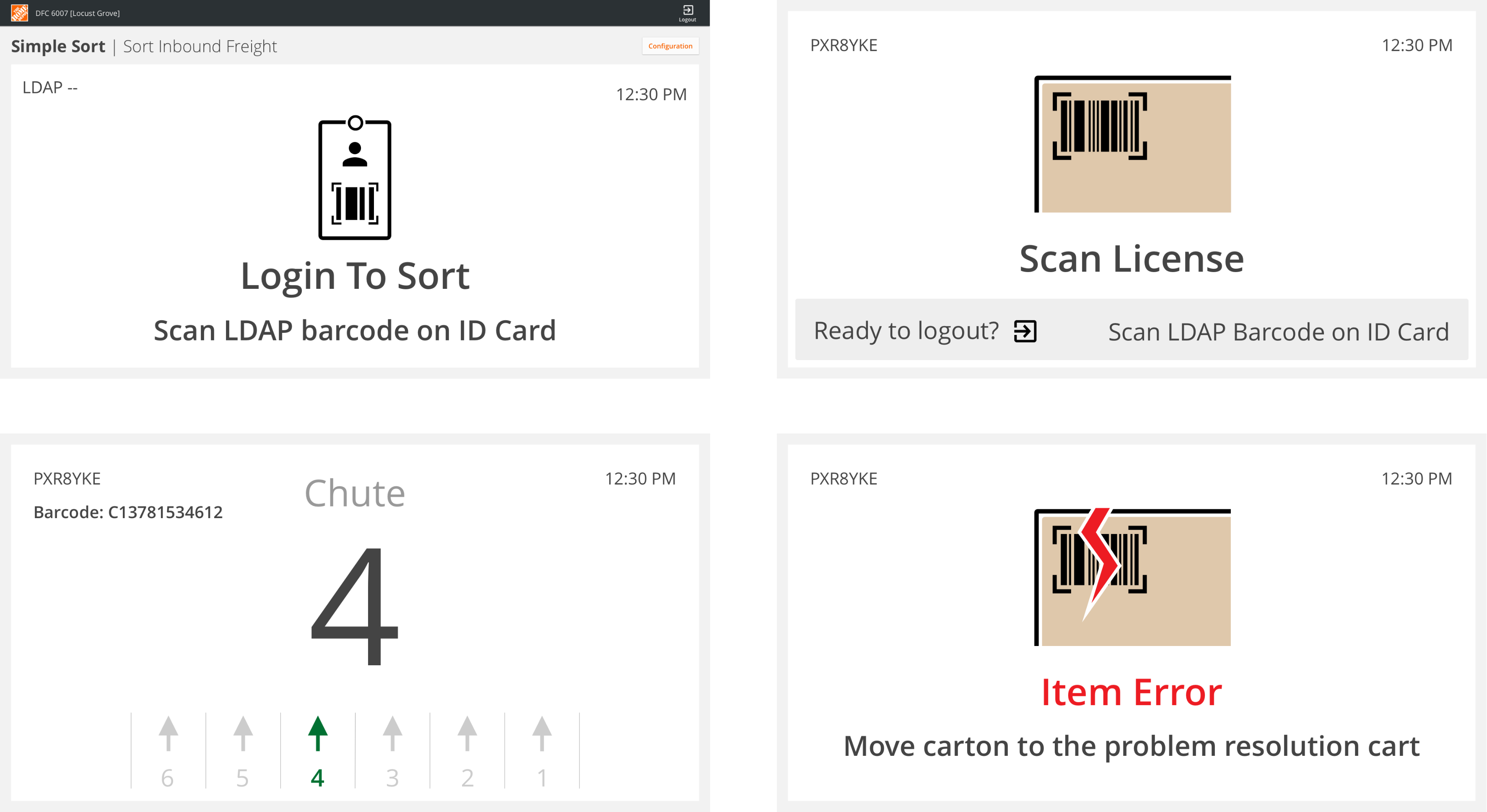

The final design of the Simple Sort App.

The final design of the Simple Sort Config App.

The app deployed in the Fulfillment Centers.

Outcomes

The Simple Sort process went live a month after the app was designed and shipped. In a month after the new process went live, we were able to see significant improvements in the unloading process.

⇨ Trailer unloading time was significantly reduced. Trailers are now being unloaded within a day.

⇨ There are no sorting bottlenecks since the items were pre-sorted based on their location which made the job of putting them away easier and faster.

Improvement in the unloading process after implementing Simple Sort system. UPH = Units Per Hour

Learnings

This project was particularly challenging during the usability studies because the Receiving associates were completely new to the Simple Sort process. Also, since the physical component of the process was not live, the associates were not familiar with the new system and process making the usability study challenging. This experience gave me a lot of learnings on running wizard-of-oz usability studies.

Other Works

Designed & Coded by Setu Kathawate © 2019